Gas Compressors

Production from oil and gas wells can be increased using compression. Reduction of backpressure in well bores, increased pressures into lines, and recovery of hydrocarbon vapors from flaring enhances production.

Unimac LP offers solutions tailored to your specific application, we focus on selecting the correct compression design to maximize recovery and minimize initial cost.

Features

- Significant gas flow enhancement

- Quiet, 70 dbA acoustic enclosure OPTIONAL

- Low maintenance design

- Designed for Class 1 Div 1 or 2 environment

- Designed for -10 F to +100F ambient

- VFD (remote) maximizes performance

- Touch screen HMI control (remote)

- State of the art instruments and controls

- Large lubricant reservoir with pump

- Air cooled steel heat exchanger

- Suction scrubber, ASME code

- Automatic condensate drain

Wellhead Enhancement Compressor Skids

Unimac’s wellhead enhancement compressor skids help reduce wellhead pressure and allow for higher flowrates of marketable products. The result is improved return on investment, even in mature or low-pressure assets.

Flash Gas Compressors

Unimac’s flash gas compressors reduce waste by capturing fugitive gases generated by transfer of hydrocarbons between low- and high-pressure separators. Liquids are separated and recirculated back into the process while gases are compressed for export, resulting in reduced flaring.

CO2 Compression Equipment

Unimac can build CO2 compression equipment to provide the high-pressure CO2 gas streams needed for your Enhanced Oil Recovery efforts.

Coal Seam Gas Products

Unimac’s Coal Seam Gas compressor skids can help you tap into gases entrapped in coal beds by removing entrained liquids and boosting pressure for sales or cogeneration.

Rotary Screw Packages

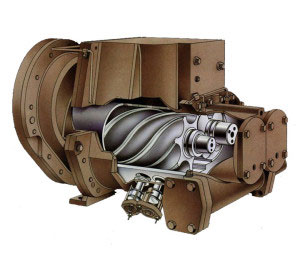

Rotary screw compressors use two closely meshing screws to compress a gas stream. Unimac uses both oil-injected and oil-free rotary screw compressors depending on application.

Rotary screw packages are cost effective and handle a very broad range of applications including wellhead compression, medium pressure gas boosting, vapor recovery, landfill gas recovery and casing head pressure reduction.

Rotary screw compressors use two meshing helical screws, (rotors), to compress the gas. The oil-flooded rotary screw compressor uses lubricating oil to fill the space between the rotors, both providing a hydraulic seal and transferring mechanical energy between the driving and driven rotor. Gas enters at the suction side and moves through the threads as the screws rotate. The meshing rotors force the gas through the compressor, and the gas exits at the end of the screws.

Lubricant is injected into the compression chamber to seal, cool and lubricate. The oil is separated from the discharge stream, then cooled, filtered and recycled.

Reliability, ease of maintenance and minimal service are top design priorities. Lubricant-coolant systems incorporate large reservoirs, circulating pumps, properly sized steel heat exchangers and synthetic lubricant specifically for the gas composition. Standard safety controls monitor lubricant levels, lubricant pressure, suction and discharge pressures as well as compressor discharge temperature.

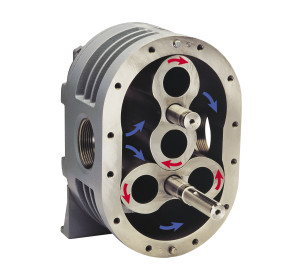

Ro-Flo Sliding Vane Compressors

Sliding vane compressors offer reduced vibration, increased differential pressure ratios, overall reduced maintenance and ability to handle a wider variety of gas compositions.

Ro-Flo sliding vane compressors consist of two types, a low and high pressure series. The low pressure models have a MAWP of 80 PSIG. The high pressure models have an MAWP of 150 PSIG.

Ro-Flo compressors can be used individually as a single stage or in series as a two-stage. The high pressure models have a drive through shaft, so a single driver can be used to drive both stages. The Ro-Flo machines can be direct, belt or VFD driven.

Multiple lubricant injection points on the unit serve to disperse the “once through” lubricant to critical areas of the machine including the vanes, cylinder bore and bearings. A liquid jacketed cylinder cools the compressor and serves to properly control thermal expansion of the components.

The Kevlar® blades have a flexural strength of more than 2.5x that of Canvas cloth blades. Average expected blade life is approximately two years and there are several recorded cases of blades lasting in excess of ten years.

Ro-Flo uses two identical cylindrical roller bearings to support the shaft within the cylinder bore. These bearings are engineered to carry the radial loading of the rotor – for a minimum L-10 life of 30,000 hours at rated compressor operating conditions.

Cylinders and cylinder heads are cast with close grained ductile iron meeting ASTM A395, which is recognized by NACE specifications. Rotor shafts for models 2CC through 12L are made of a single piece of SAE 1144 carbon steel bar stock. Models 17S-19L rotors are a single piece forged from SAE 1141 steel.

Standard shaft seals are single face mechanical type with, Viton elastomers, stainless steel spring and carbon vs. alloy steel faces. Optional John Crane double bellows seals are available and are often selected for sour or difficult to handle gas streams.

MB Lobe Blower Packages

The MB lobe blower package is specifically designed to boost well head gas flow in low pressure applications with flows from 50 to 6,000 MSCFD.

In most cases the rotary lobe blower will produce a one atmosphere (15 PSI) boost from the inlet connection to the outlet, with a maximum discharge pressure up to 25 PSIG.

Reliability, ease of maintenance and minimal service are top design priorities. A rotary lobe blower has a dry compression chamber and does not require a separate coolant-sealing circuit like a flooded screw, liquid ring or vane design. Lift-off enclosure panels with quarter turn latches make access for routine service easy.

Packages are equipped with VFD controls that cost-effectively increase production from coal bed methane and mature gas wells. The Unimac design closely monitors suction and discharge pressures automatically adjusting blower speed, staying within safe limits, while maximizing gas flow. The control system also allows blower performance to be modified quickly to meet changing wellhead conditions.

A touch-screen display allows the operator to view operating conditions or adjust operating parameters. The unit can also be controlled and monitored remotely using optional telemetry satellite or wireless communications modules.

Rotary lobe blowers are ideally suited for “unconventional gas” applications such as enhancing the rate of desorption in CBM wells or Landfill gas extraction.